Introduction

Water scarcity remains a critical global challenge, particularly in regions experiencing climate-induced drought and declining groundwater levels. Fog harvesting is a low cost, off grid, and environmentally friendly solution for water generation. By capturing microdroplets from fog through specially designed mesh structures, fog catchers provide potable water for drinking, irrigation, and sanitation.

Working Principle of Fog Catchers: A Microphysical and Engineering Perspective

Fog catchers are passive water harvesting systems that extract potable water from the atmosphere by intercepting microdroplets suspended in fog. Their functionality relies on fluid dynamics, surface science, and environmental physics. The system captures airborne water droplets through mesh materials that promote condensation, coalescence, and gravitational collection.

1. Fog Physics and Droplet Dynamics

Fog is a type of low lying cloud composed of tiny water droplets (1–30 μm in diameter) suspended in air. These droplets form under conditions of high relative humidity and specific temperature gradients, typically when warm, moist air meets cooler surfaces.

- Density of fog: 0.05–0.5 g/m³

- Typical droplet concentration: 100–500 droplets/cm³

- Velocity of wind-carried fog: 2–8 m/s (ideal range)

For fog water harvesting, the system needs to exploit the kinetic energy of these droplets, facilitating their inertial impaction onto a capture surface.

2. Capture Mechanism: Micro Scale Impaction and Filtration

The first phase involves interception of droplets as fog laden wind moves through the mesh.

Inertial Impaction

When air carrying fog droplets encounters a solid surface (e.g., mesh filament), droplets with higher inertia deviate from the airflow and collide with the surface, especially at:

- Higher wind speeds

- Smaller mesh pore sizes

- Larger droplet diameters

Direct Interception

Smaller droplets are captured through van der Waals interactions when they come into close proximity with fiber surfaces even without full collision.

Diffusion Capture

At very small droplet sizes (<1 μm), Brownian motion causes random collisions with mesh fibers. This contributes minimally but is non-negligible in ultra-fine fog conditions.

3. Condensation and Coalescence

Once droplets impact the mesh:

- They adhere due to surface tension and mesh hydrophilicity

- Coalesce into larger droplets (≥100 μm), increasing gravitational force

Key Influencing Factors:

- Surface energy of mesh material (hydrophilic > hydrophobic)

- Mesh texture (micro-roughness enhances capture)

- Ambient temperature (cooler surfaces improve condensation)

- Surface coatings (e.g., TiO₂ nanolayers improve adhesion and water spread)

4. Gravity-Driven Drainage and Collection

As droplets grow heavier, gravity pulls them downward through the mesh toward the bottom collection trough.

- The inclination angle (typically 45°–60°) assists droplet flow.

- Wicking action (in multifilament meshes) helps convey water along fibers.

- Collected water accumulates in PVC or HDPE troughs, and flows through pipes into storage tanks.

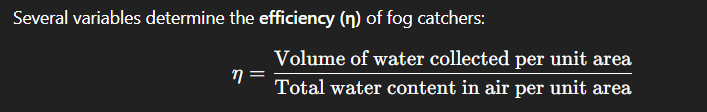

5. Efficiency Parameters

- Mesh porosity (Φ): Ideal range = 50–70%

- Fiber diameter (d): Smaller fibers increase impaction efficiency

- Mesh wettability (θ): Surface contact angle < 60° is desirable

- Wind velocity (v): Collection increases proportionally up to ~8 m/s

- Droplet size distribution (D₅₀): Larger droplets (≥10 μm) improve yield

6. Advanced Design Enhancements

Hydrophilic Surface Treatments

- Improve initial droplet adhesion

- Reduce time to coalescence

- Promote rapid droplet migration

Biomimetic Meshes

- Inspired by cactus spines or beetle wings to promote droplet transport through surface tension gradients (Laplace pressure differences)

Nanostructured Surfaces

- Hierarchical textures (micro + nano roughness) increase capture efficiency and drainage rates

- Self cleaning via photocatalytic activity or low adhesion angles

7. Simulation Tools for Optimization

To predict and enhance fog catcher performance, researchers use:

- Computational Fluid Dynamics (CFD): Simulates airflow and droplet trajectory

- Lagrangian Particle Tracking: Analyzes individual droplet impacts

- Image Analysis Algorithms: Quantify droplet size and coalescence over time

Structural Design and System Components of Fog Catchers: An Engineering Overview

The effectiveness of a fog catching system depends heavily on its structural design and integration of functional components. A well optimized fog catcher structure is engineered to maximize droplet capture, coalescence, and drainage while maintaining mechanical stability and durability in diverse environmental conditions.

1. Structural Framework

The physical frame of a fog catcher provides the mechanical support required to hold the mesh and withstand external forces such as wind pressure, corrosion, and UV degradation.

Material Requirements:

- Corrosion Resistance: Necessary due to constant moisture exposure.

- Lightweight Yet Durable: To facilitate transportation and installation in remote areas.

- High Wind Tolerance: Wind speeds in fog zones may exceed 80 km/h.

Common Materials Used:

- Galvanized Steel Tubing

- Aluminum Frames with Protective Coatings

- Fiberglass Reinforced Polymer (FRP)

- Bamboo (in low cost, eco friendly systems)

Frame Configurations:

- Rectangular Vertical Mesh Panels (1 m × 1.5 m to 4 m × 8 m)

- Tensioned Double-Pole Frames for structural rigidity

- Anchoring Systems: Deep-set ground anchors or concrete footings to prevent toppling during storms

2. Mesh or Netting Panel

The mesh panel is the critical component responsible for capturing fog droplets.

Performance Requirements:

- High surface area-to-volume ratio

- Hydrophilic surface for droplet adhesion

- Mechanical durability against UV and salt corrosion

Technical Specifications:

| Parameter | Ideal Range |

|---|---|

| Material | Polypropylene (PP), Polyethylene (PE), Nylon, HDPE |

| Filament Diameter | 0.2–0.5 mm |

| Pore Size | 0.5–2 mm |

| Porosity (ϕ) | 40–70% |

| Surface Treatment | UV stabilizer, hydrophilic coating (e.g., TiO₂, ZnO nanoparticles) |

Types of Meshes:

- Raschel Mesh: Widely used due to low cost, good fog capture efficiency, and durability

- Electrospun Nanofiber Membranes: For experimental high efficiency catchers

- Biomimetic Meshes: Engineered using surface patterning inspired by desert beetles or spider silk

3. Water Collection and Drainage System

Collected fog water must be efficiently drained and transported to storage tanks to avoid stagnation, microbial growth, or system flooding.

Components:

- Troughs or Gutters:

- Material: PVC, HDPE, Stainless Steel

- Angle: 15–30° inclination for gravity flow

- Positioned at the base of the mesh panel

- Downpipes and Connectors:

- Connect troughs to storage tanks

- Diameter: Typically 1–2 inches

- Fitted with mesh filters to prevent debris clogging

- Non-Return Valves:

- Prevent backflow during heavy rainfall or high winds

4. Storage and Treatment Units

Collected water is directed to storage systems for temporary holding, filtration, and sometimes, disinfection.

Storage Systems:

- Surface or Subsurface Tanks: Typically plastic or ferrocement tanks (500–5,000 liters)

- Bladder Tanks: Used in portable setups

- Underground Reservoirs: For long-term storage and thermal regulation

Optional Treatment Modules:

- UV-C Disinfection Units (solar-powered or electric)

- Ceramic or Membrane Filters for particulates

- Activated Carbon Columns for odor and organic impurity removal

5. Instrumentation and Monitoring (Optional in Research-Grade Systems)

Some advanced or experimental systems integrate sensors and microcontrollers to monitor system performance and environmental parameters.

Sensors:

- Anemometers: Measure wind speed

- Hygrometers: Monitor humidity

- Rain Gauges: Distinguish between fog and rainfall contribution

- Flow Meters: Track volume of water collected

- Temperature Sensors: For thermal gradient correlation

Embedded Controllers:

- Arduino Uno / ESP32 / STM32: Collect sensor data, automate valves, control solar-powered systems

- LoRa or NB-IoT Modules: Enable remote telemetry in off-grid locations

6. Mounting and Orientation Guidelines

To maximize fog interception:

- Orientation: Perpendicular to prevailing wind direction (±15°)

- Elevation: Typically installed on hilltops or coastal ridges

- Height from Ground: Bottom edge of mesh ~0.5–1 m above ground to avoid splash contamination and debris

7. Maintenance and Cleaning Protocols

- Cleaning Frequency: Once every 1–2 months (manual brushing or low-pressure spray)

- Mesh Inspection: Look for biofouling, tearing, or UV damage

- Trough Disinfection: Periodic chlorination or boiling if used for drinking water

Environmental and Design Considerations

Meteorological Factors

- Fog Type: Coastal advection fog is more productive than radiation fog.

- Droplet Size Distribution: Determines mesh material and pore size.

- Wind Speed and Direction: Affects positioning; optimal at 2–8 m/s.

Orientation and Tilt

- Perpendicular to prevailing wind direction

- Mesh tilted at 60° for optimal gravitational flow in sloped terrain

Materials and Technologies Involved

Advanced Mesh Materials

| Mesh Type | Water Collection Efficiency | Durability | Cost |

|---|---|---|---|

| Raschel Polypropylene | Moderate | High | Low |

| Stainless Steel Mesh | High | Very High | High |

| Nanofiber Mesh (PVDF) | Very High | Moderate | Moderate |

Hydrophilic Coatings

- Titanium Dioxide (TiO₂) Nano-coatings: Boost condensation rates

- Graphene Oxide Coatings: Improve water droplet spreading and capture

- Plasma Surface Modification: Alters mesh surface energy to attract moisture

Sensor Integration (Smart Fog Catchers)

- Anemometers: Measure wind speed

- Humidity Sensors (DHT22, SHT31): Monitor air moisture content

- Data Loggers: Store environmental parameters

- Flow Sensors: Quantify daily water yield

Step-by-Step Implementation Process

Step 1: Site Analysis

- Identify fog-prone regions via satellite data and weather stations

- Analyze seasonal fog frequency and wind patterns

Step 2: Mesh and Material Selection

- Choose based on environmental exposure, fog type, and maintenance budget

Step 3: Structural Design

- CAD software to simulate wind load and tension stress

- FEM (Finite Element Method) modeling for mesh-pole anchorage system

Step 4: Installation

- Erect poles and tension mesh

- Install troughs and connect to storage tanks

Step 5: Monitoring and Optimization

- Deploy sensors to log environmental and water output data

- Periodically clean mesh to avoid biofouling or dust accumulation

Performance Metrics and Efficiency

| Parameter | Optimal Value/Range |

|---|---|

| Fog Droplet Size | 10–25 µm |

| Wind Speed for Collection | 2–8 m/s |

| Water Yield (1 m² Mesh) | 1–10 L/day (depending on fog) |

| Mesh Efficiency | 10–30% droplet retention |

| Mesh Cleaning Interval | Every 2–4 weeks (manual/auto) |

Advantages and Limitations

Advantages:

- Low energy requirement (no external power source)

- Simple deployment and low maintenance

- High scalability and modularity

Limitations:

- Dependent on fog frequency and environmental conditions

- Susceptibility to vandalism and wear

- Lower water yield compared to desalination

Case Study: Deployment in Coastal Highland Region

Location: Arid mountain range near coastal belt

Setup: 20 large fog catchers (4m x 12m mesh)

Average Yield: 1500 liters/day (during fog season)

Technologies Used:

- Raschel mesh with TiO₂ hydrophilic coating

- IoT-enabled sensors for fog density and wind speed

- Water filtration unit for potable use

Outcome:

- Supported drinking needs of ~400 individuals

- Supplemented agricultural irrigation during dry months

Conclusion

Fog catchers represent an eco-friendly and technically viable solution for atmospheric water harvesting, especially in fog-dense coastal or mountainous regions. Through advancements in mesh design, nanomaterial coatings, and IoT integration, their efficiency and scalability can be significantly enhanced. With growing demand for sustainable water technologies, fog harvesting offers a practical response to climate-induced water scarcity.