Introduction to 3D Printing in Construction

The construction field is undergoing a profound transformation with the advent of 3D printing technology. 3D printing, additive manufacturing, has emerged as a groundbreaking approach that has the potential to revolutionize the way we build structures. 3D printers can construct buildings and components with unprecedented precision and complexity by layering materials and creating three-dimensional objects.

This innovative technology offers several advantages in the construction industry. It allows for creating intricate designs that were previously challenging or costly. Additionally, it has the potential to significantly shorten construction timelines and reduce labor costs, thereby offering economic benefits. Moreover, 3D printing reduces material waste by utilizing only the necessary construction-grade materials, resulting in more sustainable practices.

The applications are diverse and promising. Entire structures, such as houses and buildings, can be 3D printed on-site or prefabricated off-site and assembled later. It also creates architectural components like columns, beams, and facades. Technology has even been applied to infrastructure elements like bridges and retaining walls. While challenges remain, such as scalability and regulatory frameworks, the possibilities that 3D printing presents for the construction industry are remarkable.

Advantages of 3D Printing Technology

- Design Freedom: 3D printing enables the creation of intricate and complex designs that would be hard or costly to achieve using traditional construction methods. It allows for the realization of unique architectural forms and customized components, opening new possibilities for creative design.

- Reduced Material Waste: Traditional construction often involves significant material waste. In contrast, 3D printing technology uses only the necessary amount of material for the structure, minimizing waste and promoting sustainability.

- Faster Construction: 3D printing can significantly speed up the construction process. By automating the building process and eliminating the need for manual labor, projects can be completed minimally compared to conventional methods. This increased efficiency translates into shorter project timelines and reduced labor costs.

- Cost-effectiveness: With reduced labor requirements and minimized material waste, 3D printing can offer cost advantages in construction projects. While the initial investment in 3D printing technology may be higher, the potential for long-term cost savings is substantial.

- Construction in Challenging Environments: 3D printing technology allows construction in remote or challenging environments, such as disaster-stricken areas or extraterrestrial habitats. 3D printing offers a viable solution for rapid and efficient structure in these contexts by minimizing the need for transporting construction and equipment.

- Enhanced Sustainability: 3D printing technology promotes sustainability through reduced material waste, optimized resource utilization, and the potential for incorporating recycled or eco-friendly materials. It contributes to more environmentally conscious construction practices, aligning with the growing demand for sustainable building solutions.

- Improved Construction Quality: The precision and accuracy of 3D printing technology result in consistent quality throughout the construction process. The automated nature of printing reduces human error, ensuring higher accuracy and structural integrity in the final built environment.

- Flexibility and Adaptability: 3D printing allows for easy modifications and alterations during construction. Design changes can be implemented quickly and seamlessly, providing greater flexibility and adaptability than traditional construction methods.

The advantages offered by 3D printing technology in construction hold the potential to transform the industry, revolutionizing design possibilities, construction efficiency, and sustainability practices.

Applications in Construction Projects

3D printing technology has many applications in construction projects, revolutionizing traditional building methods. One of the primary applications is building construction, where entire structures can be 3D printed either on-site or fabricated off-site and later assembled. This approach enables faster construction, reduces labor requirements, and provides design freedom for complex architectural forms. Additionally, 3D printing is extensively used to manufacture architectural components such as columns, beams, facades, and decorative elements. The ability to customize and intricately design these components allows for unique and visually striking architectural designs.

Moreover, 3D printing finds its place in constructing infrastructure elements like bridges and retaining walls, offering more efficient construction processes and reducing costs. Beyond structural applications, 3D printing is also utilized in interior design and furniture manufacturing, enabling the creation of customized and personalized pieces. It plays a vital role in prototyping and model making, allowing architects, engineers, and designers to create scaled-down models and prototypes for testing and communication.

Additionally, 3D printing offers practical solutions for repair and retrofitting by quickly producing replacement parts on demand. Lastly, it can be employed for constructing temporary structures such as emergency shelters or event pavilions, thanks to its speed and cost-effectiveness. The applications of 3D printing in construction projects are diverse, offering improved efficiency, design flexibility, and sustainable practices in the industry.

The Role of Algorithms in 3D Printing Technology for Construction:

The construction field has witnessed a paradigm shift with the advent of 3D printing technology. Behind the scenes of this groundbreaking technology lie powerful algorithms that drive and optimize various aspects of the 3D printing process. This innovative additive manufacturing approach offers immense potential in design freedom, cost-effectiveness, and sustainability.

Slicing Algorithms:

At the core of 3D printing technology, slicing algorithms convert digital models into printable instructions. These algorithms analyze the 3D model and divide it into 2D layers, determining crucial parameters such as layer thickness, infill density, and support structures. By optimizing the toolpath, slicing algorithms ensure that the 3D printer can accurately construct the object layer by layer, resulting in a high-quality final product.

Path Planning Algorithms:

Path planning algorithms are vital in determining the movement path of the 3D printer’s robotic arm or gantry. These algorithms calculate the most efficient trajectory, considering printer kinematics, obstacle avoidance, and geometric constraints. By optimizing the printer’s movements, path planning algorithms minimize travel time and enable precise material deposition, ensuring the construction process is efficient and accurate.

Material Optimization Algorithms:

Material optimization algorithms aim to reduce waste and optimize the utilization of construction-grade materials. These algorithms analyze the digital model and determine the optimal distribution and density of material within the printed object. Material optimization algorithms optimize the internal structure, such as infill patterns or lattice structures, to achieve the desired structural integrity while minimizing material consumption, contributing to sustainable construction practices.

Support Structure Generation Algorithms:

Complex designs often require support structures to provide stability during the printing process. Support structure generation algorithms automatically generate these supports based on the geometry of the object being printed. By analyzing overhangs and other design considerations, these algorithms determine the placement and design of support structures, ensuring successful printing and facilitating the easy removal of supports post-printing.

Quality Control Algorithms:

Quality control algorithms play a crucial role in assessing the quality of the printed object and detecting any potential defects or errors. These algorithms analyze sensor data, such as temperature, humidity, or print layer characteristics, to identify deviations from desired specifications. By providing real-time feedback, quality control algorithms enable adjustments to print parameters, ensuring the final product meets the required quality and performance standards.

Building a Construction Using 3D Printing Technology: A Step-by-Step Process

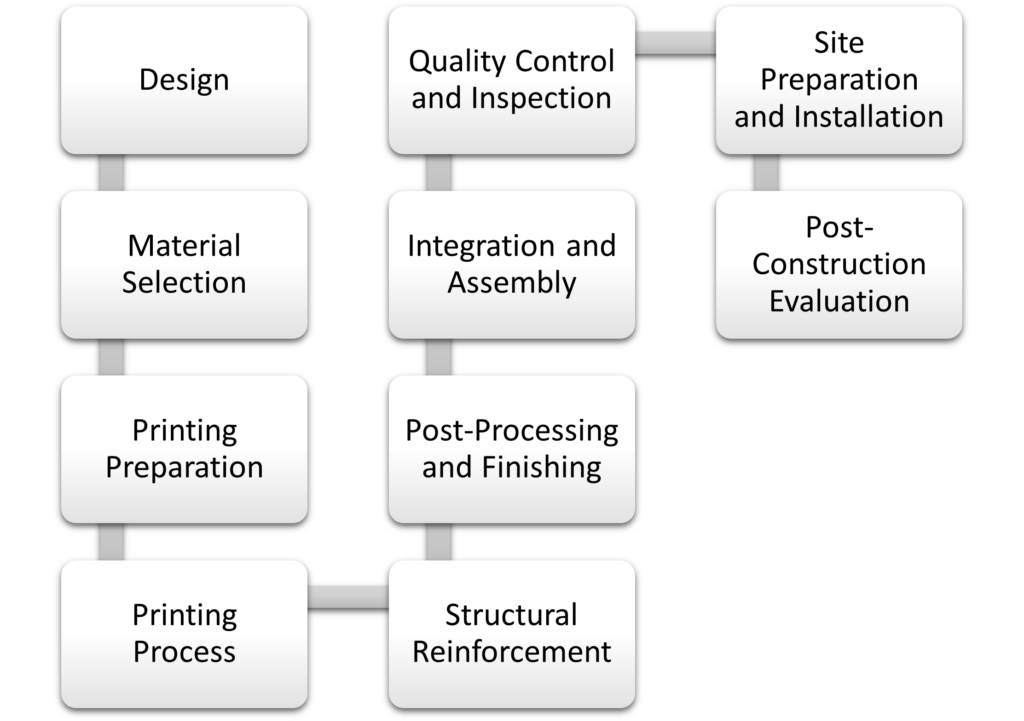

Building construction using 3D printing technology involves several key steps. While the specific details may vary depending on the project and the 3D printing technique employed, the general process typically includes the following stages:

- Design: The first step is to create a digital 3D model of the structure using computer-aided design (CAD) software. This model serves as the blueprint for the construction and includes all the necessary details, such as dimensions, architectural features, and structural elements.

- Material Selection: Once the design is finalized, suitable construction-grade materials for 3D printing are chosen. Common materials include specialized concrete mixes, polymers, composites, or other appropriate materials compatible with specific 3D printing technology.

- Printing Preparation: The digital model is then processed using slicing software that divides the model into layers, determining the path and parameters for the 3D printer. This step involves optimizing the design for additive manufacturing, considering factors such as support structures and layer thickness.

- Printing Process: The 3D printing begins with the design prepared. The printer deposits or extrudes the selected material layer by layer, following the predetermined path and parameters. Depending on the technique, the printer may use a nozzle, a robotic arm, or other specialized mechanisms to deposit the material precisely.

- Structural Reinforcement: During the printing process, structural reinforcement elements such as steel bars or fiber reinforcement may be incorporated to enhance the strength and durability of the construction. These elements are often inserted manually or integrated into the printing process using specialized techniques.

- Post-Processing and Finishing: After the printing is complete, post-processing steps are carried out to refine and finish the printed structure. This may involve removing support structures, smoothing rough surfaces, and applying additional coatings or finishes for aesthetic or functional purposes.

- Integration and Assembly: In some cases, additional components or systems must be integrated into the 3D printed structure, such as electrical wiring, plumbing, or insulation. These elements are typically installed through conventional construction methods or merged during printing if the technology allows.

- Quality Control and Inspection: Complete quality control and inspection processes to ensure structural integrity and compliance with building codes and regulations. This may involve testing the material strength, conducting structural analysis, and verifying compliance with design specifications.

- Site Preparation and Installation: Once the 3D printed structure is deemed structurally sound and compliant, it is transported to the construction site. Site preparation activities are carried out, such as leveling the ground or creating foundations. The printed components are then assembled and connected to complete the construction.

- Post-Construction Evaluation: After the construction is complete, ongoing evaluation and monitoring are essential to assess the performance and durability of the 3D-printed structure over time. This helps identify any potential issues or areas for improvement in future projects.

It’s important to note that the specific details and processes may vary depending on the scale, complexity, and 3D printing technology utilized. However, the general framework outlined above provides an overview of the critical stages of construction using 3D printing technology.

Overcoming Challenges and Limitations

Overcoming challenges and limitations is crucial for the widespread adoption and success of 3D printing technology in construction. Scaling up the technology to accommodate large-scale projects requires advancements in printer capabilities and the development of multi-printer systems. Expanding the range of printable construction-grade materials through research and development efforts is essential.

Ensuring the structural integrity and compliance of 3D-printed structures with building codes requires rigorous testing, certification processes, and standardization. Addressing cost and economic concerns involves making 3D printing more affordable and developing cost-effective materials and methods. Overcoming design complexity requires collaboration between architects, engineers, and 3D printing experts.

Establishing appropriate regulatory frameworks and bridging the skills gap through education and training programs are essential. By addressing these challenges, the construction industry can harness the full potential of 3D printing, revolutionizing how we design, build, and construct structures more efficiently, sustainably, and innovatively.

Notable Examples of 3D Printing in Construction:

The construction field has witnessed a transformative shift with the emergence of 3D printing technology. This innovative approach, also known as additive manufacturing, has opened new possibilities for faster, more cost-effective, and sustainable construction practices. Around the world, notable examples of 3D printing in construction have emerged, demonstrating the remarkable potential of this technology. From the construction of fully functional office buildings to the creation of intricate architectural structures, these examples highlight the versatility and impact of 3D printing in revolutionizing traditional construction methods.

- Dubai, United Arab Emirates: Dubai has emerged as a prominent hub for 3D printing in construction. The city has witnessed the structure of the world’s first fully functional 3D-printed office building, showcasing the potential for large-scale additive manufacturing in the construction industry.

- Nantes, France: A 3D-printed social housing project has been implemented in Nantes, demonstrating the feasibility of using this technology to address affordable housing challenges. The project showcases the potential for cost-effective and sustainable construction solutions.

- Milan, Italy: Milan has seen the construction of a 3D-printed pedestrian bridge, showcasing the application of additive manufacturing in infrastructure projects. The bridge highlights the potential for 3D printing to create structurally sound and visually appealing architectural elements.

- Moscow, Russia: Moscow has embraced 3D printing technology in construction by creating a residential building using additive manufacturing techniques. The project demonstrates the efficiency and speed of 3D printing for constructing multi-story buildings.

- Beijing, China: Beijing has showcased 3D printing in construction by constructing an impressive 3D-printed villa. The project highlights the potential for using this technology to create intricate and customized architectural designs.

The widespread adoption of 3D printing in construction reflects its potential to revolutionize the industry and shape the future of building construction. These notable examples from various locations demonstrate the global impact of 3D printing in construction. They showcase how different regions embrace this technology to address housing challenges, create innovative infrastructure, and explore new possibilities in architectural design.

The Future of 3D Printing in the Construction Industry

3D in the construction industry has gained significant momentum in recent years, revolutionizing traditional construction practices and unlocking new possibilities. As this innovative technology continues to evolve and mature, its future holds tremendous potential for profoundly shaping the construction industry. From enhanced design capabilities to sustainable construction methods, the end of 3D printing in construction is poised to drive innovation, efficiency, and sustainability to new heights.

- Design Freedom and Complexity: 3D printing offers unparalleled design freedom, allowing architects and engineers to create complex geometries and intricate structures that were once difficult or impossible to achieve with conventional construction methods. As technology advances, we can expect to see even more incredible design possibilities, enabling the realization of visionary architectural concepts and pushing the boundaries of creativity in construction.

- Rapid Construction and Time Efficiency: 3D printing has the potential to significantly reduce construction timeframes by automating and streamlining the building process. As printers become faster and more efficient, entire buildings could be constructed within days or weeks, revolutionizing project delivery speed and enabling rapid responses to housing and infrastructure needs.

- Sustainable and Eco-Friendly Practices: 3D printing in construction has the inherent advantage of minimizing material waste and reducing the carbon footprint, which is generally associated with traditional construction methods. The ability to precisely deposit materials where needed and utilize eco-friendly fabrics and recycled components holds the promise of creating more sustainable and environmentally friendly buildings.

- Customization and Personalization: 3D printing enables high levels of customization, allowing for tailored designs and personalized construction solutions. This technology can accommodate individual requirements, adapt to site-specific constraints, and meet clients’ needs. From customized facades to interior fixtures, 3D printing opens a world of possibilities for customized construction.

- On-Site Printing and Remote Construction: Bringing 3D printing technology directly to the site offers immense advantages. On-site printing reduces transportation costs, simplifies logistics, and enables construction in remote or challenging locations. This capability has the potential to revolutionize disaster response efforts and provide rapid housing solutions in crises.

- Collaboration and Integration: The future of 3D printing in construction relies on cooperation between industry stakeholders, including architects, engineers, contractors, and material scientists. By integrating their expertise and knowledge, advancements in materials, processes, and design methodologies can be made, fostering a holistic construction approach and driving innovation throughout the industry.

As research and development continue, the future of 3D printing in the construction industry holds enormous promise. From pushing the boundaries of design and construction to addressing global housing challenges and advancing sustainable practices, this technology is poised to transform how we build and shape our built environment. With ongoing advancements and a collaborative mindset, the future of 3D printing in construction is set to redefine the industry, unlocking unprecedented opportunities for innovation, efficiency, and sustainable development.

Conclusion: Transforming the Way We Build

3D printing technology has emerged as a transformative force in the construction industry, offering a glimpse into a future where traditional construction practices are revolutionized. From its current applications in creating buildings, bridges, and customized components to its potential for design freedom, rapid construction, sustainability, and on-site printing, 3D printing is poised to transform how we build and shape our built environment.

The notable examples and advancements in 3D printing showcased in this article demonstrate the incredible potential of this technology to drive innovation, efficiency, and sustainability in construction. As technology continues to evolve and mature, overcoming challenges and limitations, it promises to unlock new possibilities, enabling us to construct complex structures with incredible speed, precision, and customization.

The future of 3D printing in construction relies on collaboration and integration among architects, engineers, contractors, and material scientists. Together, they can push the boundaries of design, develop advanced materials, refine printing processes, and establish appropriate regulations and standards. This collaborative mindset will pave the way for continued innovation and adoption of 3D printing technology in the construction industry.

As we look ahead, 3D printing is transforming how we build. It offers solutions to housing shortages, rapid construction needs, and sustainability challenges. The future of construction will be shaped by this technology, unlocking new possibilities, unleashing creativity, and redefining how we approach the built environment.

With ongoing research, technological advancements, and a shared vision for a more efficient and sustainable future, 3D printing has the potential to revolutionize construction practices, leading us into a new era of building where imagination knows no bounds. The future is bright, and the transformational power of 3D printing in construction is set to reshape the industry for the better.